Dual fuel heat pump packaged rooftop units (RTUs) offer a versatile and energy-efficient solution for heating and cooling commercial buildings. By combining the efficiency of a heat pump with the power of a gas furnace, these units provide optimal comfort and performance in various climates.

Heat pumps have a lot of benefits for the climate and performance. They also have some challenges around efficiency at cold temperatures, and there are concerns about grid performance if and when a lot of heat pumps and trying to heat at the same time.

Dual fuel heat pumps are the best of both worlds – maximum performance, and then back up natural gas or electric resistance heat below a certain temperature. In this article, we will explore more as well as discuss a pilot program from our local utility to study and explore these new heat pumps.

What are the Benefits of Dual Fuel Heat Pump RTUs?

One of the primary benefits of dual fuel RTUs is their enhanced energy efficiency. During mild weather conditions, the heat pump can effectively heat and cool the building, reducing reliance on the gas furnace. This results in lower energy consumption and reduced utility bills. Additionally, the gas furnace can provide backup heat during extremely cold temperatures, ensuring consistent comfort even in harsh conditions.

Another advantage of dual fuel RTUs is their flexibility and adaptability. These units can be customized to meet the specific needs of different building types and sizes, making them suitable for a wide range of commercial applications. Moreover, dual fuel RTUs often incorporate advanced technology, such as variable-speed fans and intelligent controls, to optimize performance and minimize noise levels.

Finally, dual fuel RTUs can contribute to a more sustainable and environmentally friendly future. By reducing reliance on fossil fuels and increasing energy efficiency, these units can help to lower greenhouse gas emissions and promote a healthier planet.

How is the Efficiency of HVAC Measured?

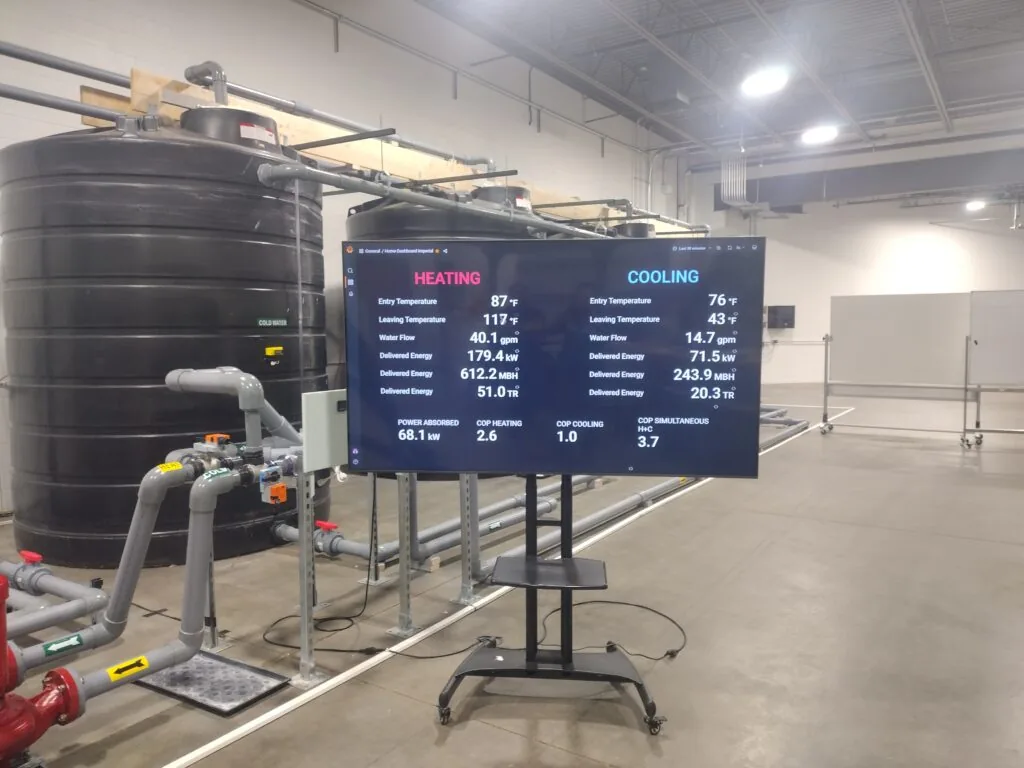

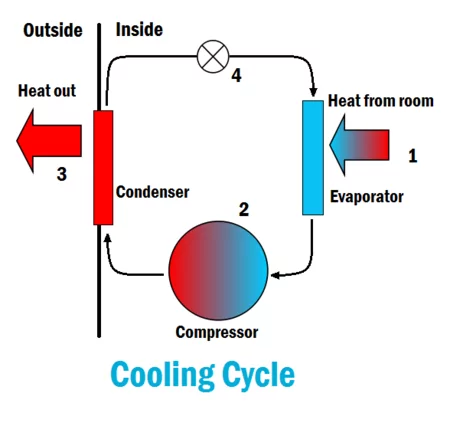

In the realm of Heating, Ventilation, and Air Conditioning (HVAC), COP is a crucial metric used to assess the efficiency of equipment, particularly heat pumps. COP, which stands for Coefficient of Performance, quantifies how effectively a system converts energy input into useful output.

A higher COP value indicates a more efficient system. For heat pumps, the COP is calculated by dividing the heat delivered to the space by the electrical energy consumed. This means that a heat pump with a COP of 3 delivers three units of heat for every one unit of electricity used.

Several factors influence a heat pump’s COP, including the outdoor temperature, the system’s design, and proper installation and maintenance. Generally, heat pumps operate more efficiently in milder climates, as they can draw heat from the outside air more effectively. Additionally, well-maintained systems with advanced technologies like inverter compressors can achieve higher COPs.

Understanding COP is essential for making informed decisions when selecting HVAC equipment. By choosing a system with a high COP, you can reduce energy consumption, lower utility bills, and minimize your environmental impact.

What is the COP of a Heat Pump?

A heat pump’s Coefficient of Performance is a measure of its efficiency in converting electrical energy into heat. While heat pumps are generally more energy-efficient than traditional furnaces, their COP can decrease as outdoor temperatures drop. Above freezing temperatures, the COP of a heat pump can be 3.5 to 4.0, which is incredibly high. In fact, another way of saying this is that heat pumps are 350% to 400% more efficient than traditional sources likely in place in your building now. However, below freezing, the COP can drop and get closer to traditional means of heating.

The primary reason for the decline at cold temperatures is the increased difficulty in extracting heat from the colder air. As the temperature decreases, the heat pump’s evaporator coil struggles to absorb enough heat from the outside environment. This reduced heat absorption can lead to a decrease in the overall efficiency of the system.

Additionally, colder temperatures can also increase the frequency of defrost cycles. During defrost, the heat pump’s evaporator coil is heated to remove frost buildup, which can temporarily reduce its heating capacity and increase energy consumption.

However, it’s important to note that modern heat pump technologies have made significant strides in improving their performance at lower temperatures. Many newer models incorporate features such as inverter compressors and advanced defrost controls to help maintain a higher COP even in colder climates.

These gains are typically seen in Variable Refrigerant Flow systems, which are more ideal for a commercial building if budget is not a concern. However, while they perform much better in modern days than the previous generation of heat pumps, they still involve a lot of construction and changing of the design of the system.

For those buildings that have limited budget, a dual fuel heat pump system combines the benefits – great COP and efficiency 90% of the year, with natural gas or electric back up on those days that are way below freezing.

What is better as a backup to a heat pump, natural gas or electric resistance?

When considering heating options for a home or commercial building, efficiency is a crucial factor. Natural gas and electric resistance heating systems have distinct characteristics in terms of COP.

Electric resistance heating systems are relatively simple in design. They convert electrical energy directly into heat by passing a current through resistive elements. While these systems are easy to install and maintain, they have a lower COP compared to natural gas heating. This is because they convert all the electrical energy into heat, without any intermediate steps.

Natural gas heating systems, on the other hand, utilize a combustion process to generate heat. Natural gas is burned in a furnace or boiler, releasing heat that is then transferred to the living space. Due to this process, natural gas heating systems can achieve higher COPs than electric resistance heating. This is because the combustion process is more efficient in converting the energy in natural gas into heat.

However, the COP of a natural gas heating system can vary depending on factors such as the efficiency of the furnace or boiler, the quality of the installation, and the local climate. Older or poorly maintained systems may have lower COPs. Additionally, the efficiency of natural gas heating can be affected by factors like the quality of the natural gas itself and the altitude of the location. Traditional packaged RTUs have an 80% efficiency by design, so the COP is never going to exceed 0.8.

Electric resistance is in theory a 1.0, since all of the energy that goes in is converted into heat. While the COP may be higher than natural gas, the cost may also be higher as electricity tends to be more expensive at similar COPs than natural gas in our current environment in 2024 in Illinois. That may change in the future, but for now, we recommend natural gas as a backup for several reasons.

Why Do We Recommend Natural Gas as a Backup instead of Electric Resistance Heating?

There are three main reasons – grid stability, costs, and existing natural gas lines.

When it is very cold out, especially when a polar vortex occurs, we have seen both some concerns around our grid as well as temporarily higher costs for electricity. For now, using natural gas during those times seems the most logical.

Natural gas is also very inexpensive in Illinois compared to other states and regions. While that may not maintain into the future, the moment makes this an important consideration for Return on Investment and Payback – both critical decision points.

Finally, if your building already has natural gas lines to your current packaged RTU, keeping those lines in place is easy and affordable (as opposed to running new lines). There are reasons to remove all of the natural gas costs to a building, including removing the expensive monthly fee for service. But you must also remove all of the cooking equipment, water heating and heating sources for an entire building, which can be an expensive undertaking.

What Are Next Steps?

If this is appealing to you, and you have a packaged RTU that is over 10 years old, the first step is to set up an energy efficiency assessment for your building. It is important to look at a building as a whole vs just one component.

In fact, in 2024 and 2025, our local utility company (Comed) has a pilot program through the Center for Energy and the Environment that is incredibly generous to explore this new technology. It could cover a lot of the cost for those interested in making this kind of transition – higher incentives than we have ever seen on packaged HVAC units. Those higher incentives will come with some interviews and data collection – but our experience has been that those are more than worth it.