Heating & Cooling Equipment – Deep Dive into Energy Efficiency

Jun 11 2022

The biggest power draw in any building is heating and cooling – so any conversation around saving energy and costs must include those two big aspects of energy usage. We will take a deeper look at this equipment, as well as ways to save energy.

Common equipment types

The most common style of heating and cooling for commercial buildings is the packaged rooftop unit or RTU. This style of heating has both heating and cooling in the same “box”, providing simplicity on the internal ductwork. Air comes from inside the building to the unit (via the return ducts), the air is heated or cooled, and then delivered throughout the building at a comfortable temperature.

Code requires that a certain percentage of outside or “fresh” air is always included in this delivered air. While this is safer for internal occupants – this outside air has to be heated or cooled and this leads to the waste in energy. This packaged RTU system is common in libraries, fast food restaurants, and commercial office buildings.

Alternatively, some heating and cooling systems are called split systems, meaning that the heating unit is inside the building and the compressor for air conditioning is on the exterior of the building. This is common in smaller commercial spaces, and we often see them in fire stations. This style of system is very common in residential systems, as well.

Boilers are commonly responsible for heating in larger and older buildings, especially multifamily buildings and large religious buildings. Original boiler systems use steam, while more modern “hydronic” boilers use hot water that runs through pipes to heat the space. This equipment connects to a radiator and can also be seen often in radiant floor heating applications. Heat produced by these methods can be very comfortable and efficient styles of heating.

They are not without their upkeep and steam systems, for example, have “traps” that require maintenance over their lifetime. They can often get blocked and can lead to inefficiencies. Natural gas energy efficiency programs get much of their energy savings from insulating the pipes of these systems, as well as updating steam traps that are no longer working.

Chillers are large cooling systems, with the same concept as a packaged or split compressor system – but much larger in scale. They have huge pipe systems that deliver cooling to the building, often with small local systems that provide cooling to a room or area. Chillers are more common in large libraries, high rise buildings, and large community buildings.

Coming soon to a building near you

Finally, there are new heat pump systems (air-source) that are coming to market, as well as geothermal (ground-source) heating and cooling systems. These are at the cutting edge of HVAC systems technology, and the future of our buildings’ heating and cooling.

Where are there efficiency gains?

There are many efficiency ratings for HVAC equipment – including SEER, IEER, EER and Energy Star. When we look at commercial equipment, we are often looking for new equipment that is within the top quartile, or 25%, of modern efficient equipment. They are often more expensive, and since they are not as common on the marketplace, harder to source.

Fortunately, there are often rebates that cover more than this increased cost and the key is to proactively replace equipment before they fail (so you can mitigate the longer lead time on high efficiency equipment).

What can make existing units more efficient are the use of the following technologies: VFDs (variable-frequency drive) or VSDs (variable-speed drive), multistage heating and cooling, DCV, or demand control ventilation, and economizers.

VFDs and VSDs motors circulate air throughout our systems, getting the cooling and heating to our working spaces. Historically, fans have been either on or off – running at full speed when the system is calling for heating or cooling and off when not. However, modern variable fan or speed drives can run at all different speeds and are associated with huge energy savings.

The old school versions of heating and cooling units were either off or on, or single stage – heating/cooling or not. Modern units can do multistage heating or cooling, meaning that they can add or remove BTUs in stages of effort. There are huge benefits to this for efficiency and equipment health. First – compressors hate to be turned on and off and that is what hurts their lifespan. When a smaller compressor is running often providing a small amount of cooling – it is both more efficient and better for the equipment.

But – another huge benefit – it removes more moisture and reduces indoor humidity during the summer – so you can keep your thermostat higher and be more comfortable while using less energy. However, on those really hot days, another stage can kick in and bring down the temperature when needed – so you get the benefits of both comfort and performance (and energy savings).

DCV, or Demand Control Ventilation, utilizes sensors to detect the demands of the space and to bring outside air in as needed. Local building code often requires outside air to come in – both to avoid buildup of CO2 from too many people, but more importantly, to get fresh air into a space to remove all of the off gassing from paints, equipment, carpeting, and other inside building contaminants.

This code, while keeping us safe, also wastes energy by always bringing in outside air on very cold and hot days. In fact, your equipment needs to work 15-20% harder to heat and cool spaces – wasting energy and reducing the life of equipment by running compressors and heat exchanger usage. While we have seen the incredible importance of outside air in the new norm of Covid – we also want that when there are people inside a space.

Modern equipment allows you to do this smartly – by demand control ventilation. This can be done via DCV with a CO2 sensor inside your space, and it triggers the economizer to bring in fresh air when over a certain threshold. Today – we are at 417 ppm in the atmosphere – while we were less than 320 ppm in the early 1960s. So CO2 sensors in your building can be set to 450 or 500 ppm – telling a unit that it is heavily occupied and needs some fresh air.

That fresh air damper will open to bring in air until the space drops below. Instead of always bringing in 15% of outside air, including unoccupied times, you only “smartly” bring in outside air when occupancy requires it. In fact, much of our modern equipment can be scheduled to bring in outside air before occupancy for even greater safety and energy efficiency.

Economizers or Free Cooling Economizers are integrated into packaged rooftop units, and allow buildings to bring in outside air when it is cooler than inside air – as it often happens in the summer evenings. This is called free cooling – and depending on the building usage and design – can happen more often than you’d think. Many rooftops for fast food restaurants have the packaged RTU compressor working to cool the kitchen on a 40-degree day. A simple open economizer will save a ton of energy in this application.

What about heat pumps?

Heat pumps are coming to the market, with improvements happening each year on the technology side. Heat pumps work like an air conditioner in reverse and can heat and cool the same space. While historically they have struggled to keep up with severe cold weather, many manufacturers are making units that maintain solid heating up to -20 degrees F. Heat pumps have the added benefit of electrifying a building and removing the gas requirement for heating, often saving a significant monthly expense.

Verde is working on a pilot program with ComEd that involves combining heat pumps with energy recovery ventilators, helping to both improve indoor air quality while saving significant energy costs. Our first project is with a huge religious and community center in Oak Park, Illinois – replacing a chiller, boiler and 5 RTU system with an advanced Energy Recovery Ventilator and heat pump system offset by over $250,000 of utility incentives.

Buildings exploring this advanced technology will also add higher quality air for their space (lowering Covid risk for occupants), as well as electrifying a building for lower carbon impact.

How about larger heating and cooling systems?

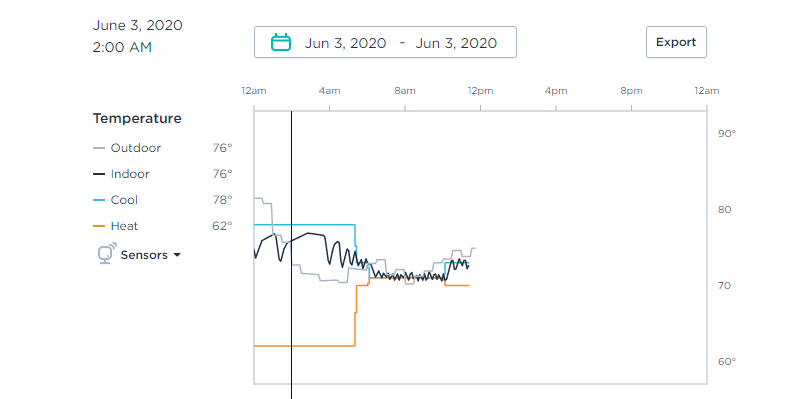

Larger systems are often controlled by something called a Building Automation System (BAS). This system controls all of the building heating and cooling systems in one centralized software. The original design intent of these large buildings and systems often degrade slowly over time – and a Retrocommissioning Program can help to tweak these systems to get them back to their original optimization.

Retrocommissioning Energy Savings Program provides an in-depth engineering study for larger buildings, and then makes recommendations for simple paybacks (1.5 years or less) and provides incentives to help implement those recommendations. In 2021, Verde began this process with a high rise apartment building, a hotel, and a process manufacturer.

While all very different – each of them benefit from a detailed engineering study and recommendations that can be implemented and lead to immediate and long term savings. Each building will also benefit from a better understanding of their equipment and upgrade potential for those equipment on a capital improvement level.

What’s going on with R-22?

One last note in the nudge of the environment in terms of equipment: R-22 was a commonly used refrigerant. It is being phased out, which is great news for our ozone and for the fight against climate change as R-22 is 2,000 times more potent at trapping heat than CO2 in our atmosphere. R410-A is the new standard on all equipment being made and manufactured.

What does that mean for existing equipment? Since R-22 is no longer being made – it will cost likely 4 times more to recharge older equipment in 2022, and that price will only continue to increase as the supply is depleted of R-22. So if sustainability, reduced maintenance costs, better air quality don’t drive your decision for upgrades to energy efficient HVAC equipment in 2022 – perhaps the fear of a $1,000 service charge in June to recharge your equipment will make the decision more important.

Since HVAC uses the most energy in a building, and climate change and Covid are arguably the two most pressing challenges of our time – updating your buildings HVAC system could be the most important decision your organization makes in 2022.

Featured Posts

Mar 15 2021

Energy Savings Formula

In 2002, I became a firefighter in the north suburbs of Chicago. I was young and idealistic - loving almost every part of the job. However, I had another secret passion - sustainability. In addition…

Continue Reading >

May 02 2019

Verde Energy Efficiency Experts 10 Most Sustainable Companies in Chicago

In our energy efficiency consulting firm, we constantly look for inspiration from local companies that lead and innovate in clean energy and sustainability. Not all companies have billion dollar budgets, but that doesn’t mean that…

Continue Reading >

Related Articles

May 08 2024

Decarbonizing Hotels – Is it Possible?

Lower Energy Cost Hospitality with Decarbonization Hotels are huge energy users - with a lot of guests that come and go quickly, keeping them comfortable is no small task. As we look ahead at decarbonization…

Continue Reading >

Feb 26 2024

What is Demand Control Ventilation?

Outside air for building, brought in via a rooftop unit, a Direct Outside Air System, or via an Energy Recovery Ventilator, are important for many reasons due to code. Fresh air is required in public…